Our passion for aviation and our clients’ success is what fuels us. Our cutting-edge products demonstrate our love for the industry, which is why we’re here. But let’s be honest about why we go to work… Just like any business, we’re in this to make money.

In our last two articles, we nailed down the importance of solid operational control and bulletproof safety practices—two essential pillars of success. But what’s perched at the very top of this business pyramid? The true motivator why we go to work. You guessed it: the cold, hard cash!

So, with operational control and safety squared away, let’s talk about the final frontier: cost control.

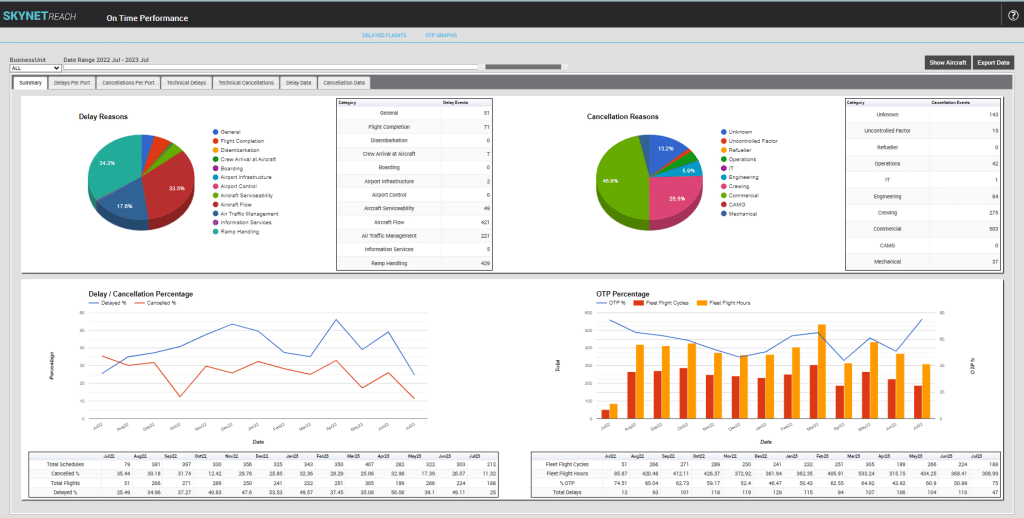

The True Cost of Delays

In your operation, do you know how much each minute of delay costs? We bet you don’t, and that’s ok. We can help.

From working with countless airlines we have found it is a question several managers struggle to answer. But here’s the thing – understanding these costs is vital for making smart decisions in your Operations Control Centre (OCC). In aviation, every minute counts, and knowing the financial impact of delays can be a game-changer in how you handle disruptions.

Evaluating the Real Costs

When we talk about the cost of delays, it’s not just about tallying up lost revenue or extra expenses, and sweeping it under the WX delay code. It’s about grasping the full picture. The sum of the direct and indirect costs to the business.

Let’s go a little deeper then, shall we?

Direct costs, such as fuel, crew overtime, maintenance, and passenger compensation. The obvious costs that are the first to be analysed on that cringeworthy spreadsheet (sidenote – if your business is using spreadsheets, please reach out as there are far better ways of working, and don’t worry, we won’t judge!) And then there are the indirect costs, which can involve reputational damage, customer dissatisfaction, and the potential loss of future business.

And lets not forget opportunity costs as the resources used to manage delays could be utilised elsewhere for greater efficiency and productivity in your OCC.

Similarly, the cost of not doing anything—choosing inaction over intervention—can be just as significant. This includes prolonged disruptions, compounded delays, and a deteriorating passenger experience.

Are cost considerations part of the regular decision-making process in your OCC? Integrating cost awareness into everyday operations can help you make more informed choices that balance efficiency, safety, and financial performance. Meticulous forward planning is only as valuable as its execution, is there a successful communication channel between your planning and operational teams regarding cost discussions?

Regular reviews are essential to ensure your resources are optimised. How many licences are you paying for? Are they the right tools for the job? Do they enhance productivity, or do they come from an era when Super Mario Bros was considered advanced tech and you still had to rewind your VHS tapes before you took them back to Blockbuster… Put another way, if some of your tech is older than the most recent round of recruits in your OCC, you need to do a tech review!

What is the cost of bringing in staff on overtime compared to the benefits? Analysing overtime costs against the advantages can help in making strategic rostering decisions.

How well do you understand the gap between planned and actual performance? The answer here is critical. If you planned to operate at a certain efficiency level but achieved less, what was the financial impact? Conversely, if you exceeded expectations, what cost savings were achieved?

By making informed decisions, you can boost your airline’s financial performance. In this industry, where every minute (and every dollar) counts, knowing your costs is the key to smarter, more efficient operations.

If you need assistance in evaluating and controlling these costs, or would like to see how your airline is travelling in a broader context, our OCC Healthcheck is a great place to start. Designed to give industry specific insight, and will take you approximately 10 minutes to complete.

Or alternatively, if you would like a demonstration of our systems or to learn more, please reach out to us today.